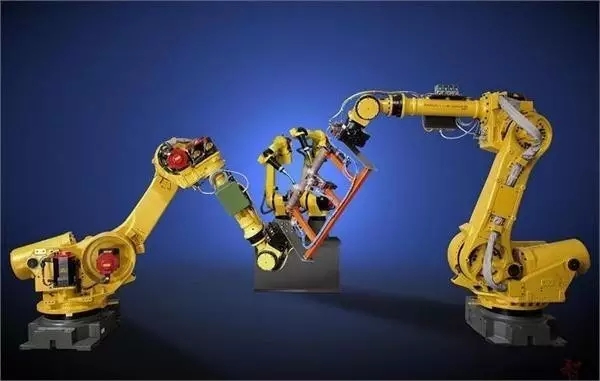

In recent years, China has gradually entered the aging society, the development of traditional labor-intensive enterprises is increasingly restricted.As a labor-intensive industry ,it’s more and more difficult for recruitment in PCB manufacturing industry . Applications of industrial robots have brought new impetus for the PCB industry.The fabrication mode that use the robots to operate the automation equipment, is gradually replacing the fabrication mode that human operate the automation equipment.What are the advantages that robots engaged in PCB manufacturing industry instead of human?

1.Using robots can avoid potential threats that operating environment cause for workers’ health and safety,which save the investment in environmental security.

2. To enhance the accuracy of the job, improve product quality. Robot can use programming and vision system to achieve accurate positioning and repeat-ability,which effectively improve the quality of the product.

3.Effectively reduce material consumption rate.

4. To reduce labor, to expedite the work rhythm, to improve work efficiency. Robots can achieve higher-speed repetitive actions, can be much higher than the manual work rhythm,which lead to significantly enhancing the efficiency and reducing the costs of labor and management.

5.The robots can make the pcb manufacturing process flexibility. In future ,PCB industry will appear more and more small batches orders. Use of industrial robots can greatly improve production flexibility, to achieve rapid delivery of orders.

6. Reduce the state influence that cause by repetitive or boring process for workers .This state influence can lead to the decline of efficiency and quality.

7. Optimization of PCB manufacturing processes, reducing the space occupied by the production operations.

8. Continuous operation of 24 hours and work under black light environment;

9. To enhance the brand image and reputation. Applications of industrial robots make the level of automation of PCB manufacturers further enhanced,and can drive the progress of product quality, production efficiency, cost control, responsiveness, which improve the overall competitiveness of the manufacturers in the industry.

In fact, after conclusion,you can easily fint that the benefits that using industrial robote brings are mainly to improve the production efficiency,and to reduce some costs caused by hirer,and to improve product quality,and to provide the impetus for company competition.