Quick Turn & Competitive Price

Express PCB service, 24H lead time.

2L PCB prototypes start from $12

4L PCB prototypes start from $49

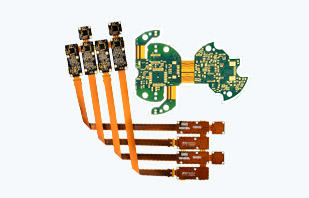

Full Feature PCB

Standard PCB, Flexible PCB,

Rigid Flex PCB, High TG PCB,

Heavy Copper PCB, Rogers PCB

PCB Assembly Service

High Quality PCB Manufacturing,

Original Components Sourceing,

Turn-key PCB Assembly Service

Facebook

Facebook Google+

Google+ Twitter

Twitter